ASSY®plus VG, socket head hardwood screw

ASSYplus VG steel, yellow zinc pl FT cylind hd AW

SCR-CYL-WO-VG-AW50-(A2L)-10X120/97

Art.-no. 0165310120

EAN 4049557072036

Register now and access more than 125,000 products

- Ideal for structural reinforcement (compression and lateral tension) of timber elements, as well as for creating wood-concrete composite floors.

- The small socket head is perfect for inconspicuous or recessed joints.

- Very high load capacity

- Very small edge distances (as pre-drilled)

- Pre-drilling option permitted

- Screw-in angle 0°-90°

- Approved for hardwood, KERTO/LVL, laminated wood and other wooden materials

- Wide product range from 6 x 80 mm to 10 x 800 mm

- For application in use classes 1 and 2 in line with EN 1995:2013

Drill tip:

Very small permissible edge distances, e.g. 3xd - d = 8 mm 60¬mm support. Pre-drilling not required as the wood does not split or break

Thread:

Symmetrical full thread for high load-bearing capacity. Lubricant coating: Enables easy screwing in and reduces the screw-in torque

Socket head for universal use

- Reduced cracking thanks to the small head diameter

- The screw can be sunk deep into the wood

AW® drive

Improved force transmission

- Optimum centring

- Long service life

- Uniform force distribution prevents damage to the surface coating

Material:

High-strength steel for high breaking torque / yellow zinc plated

The requirements of the European Technical Approval must be observed.

Würth's dimensioning software (either online, or you can download it for offline use) can be used to perform a customised static calculation. For standard applications, our manual "Timber carpentry - ASSY structural screws" is available. This manual can be downloaded free of charge from our website www.wuerth.it.

Dimensioning software, data sheets and European technical assessments can be found on our website www.wuerth.it.

ETA-11/0190

ETA-13/0029 (from 8 x 160 mm to 10 x 580 mm)

Datasheets(X)

The ASSYplus VG screw is a full-thread screw that can be used universally within the new construction and renovation sector for timber construction, carpentry, timber prefab and element construction. Structural reinforcement through compression and tension lateral to the timber grain.

Lateral compression and tensile reinforcements

Lower compression and tensile forces across the wood grain. The ASSYplus VG screws allow you to increase the compression and lateral tensile strengths of the wood, using less timber and designing more effectively.

Lateral tension reinforcement, reinforcement of beams that contain notches and holes

Reinforcement for preventing failure of glued trusses or other supports by exceeding the tensile strength of the wood can be carried out quickly and reliably with the ASSYplus VG. Compared with conventional reinforcements such as glued-in threaded rods or side beam reinforcements using wooden material panels, this enables visually appealing solutions and significantly reduces the required assembly time.

Lateral tensile reinforcement with ASSY plus VG when connecting main and secondary beams with steel parts:

The weak point when connecting main and secondary beams with steel parts is the top centre connecting row of the nails (danger of cracking). The lateral tensile reinforcement of the main beam using the ASSY plus VG in the beam connection area can eliminate the risk of lateral failure.

Lateral compression reinforcement for support beams

With a truss support, the ASSY plus VG absorbs the compressive force to be transmitted. The head, together with the screw thread, improves the strength of the screws when a steel plate is placed between the components and distributes this strength evenly across all full thread screws in the entire cross section of the wood. The load-bearing capacity of the support is increased and compression of the wooden cross-section is avoided.

Connection of main/secondary support beams

To date, main/secondary beam connections are made with steel parts, such as joist hangers or concealed beam connectors that are time-consuming to install. ASSYplus VG screws save time and create invisible joints. By screwing in the ASSY plus VG at an angle of 45°, the screws absorb the lateral forces of the connection. Ideal applications: FT-fix setting template.

False edge and lateral support beam reinforcement

It is often necessary to reinforce existing beams or rafters, especially when renovating old buildings. For reinforcements, the ASSY plus VG screw offers effective, cost-efficient technologies for increasing load-bearing capacity of the beams and reducing bending.

Prefabricated house construction/timber frame construction

ASSY plus VG is the optimum problem-solver in prefabricated house construction. Thanks to its full thread, it can absorb significantly greater tensile, pressure and shear loads. The connection strength is therefore not limited due to exceeding the head pull-through resistance but is ensured by the full thread. The drill tip ensures that the substructure does not splinter or crack during screwing in when the short edge distances are complied with, which is often the case with screws without a drill tip.

Rafter and purlin connection

Current rafter-purlin anchors require time-consuming assembly and also have a low load-bearing capacity. The ASSY plus VG is therefore an effective alternative with benefits in terms of assembly time. The existing weak point of an ASSY 3.0 countersunk head screw or an ASSY 3.0 SK, the head pull-through, can therefore be ignored with the ASSY plus VG. The result is a lasting connection even if the wooden cross-section subsequently dries out and shrinks.

Purlin connection

In the construction of commercial and industrial buildings, the rafter-supporting purlins are generally formed as coupling purlins. The single-field beam coupling is used to create multiple field beams. The load-bearing capacity is increased and, in return, smaller material cross-sections can be used. With ASSY screws, a quick and easy connection can be created. An ASSY SK screw (consolidation) and, depending on the load, ASSY plus VG screws, 6 or 8 mm in diameter, are inserted at right angles at each connection point. Pre-drilling is not necessary. The wood cross-sections can be kept small due to the short edge distances of the ASSYplus VG. Compared to a pin mounting system, the elaborate setting of nuts and rods is eliminated, as is the need to subsequently tighten the bolt nuts correctly. A powerful cordless drill is all that is required for installation of the screws.

Main/secondary beams for walls/floors

When traditionally designing houses with a timber frame construction, it used to be common practice to build walls floor by floor. The footing beam therefore always lay on the wall frame of the floor below. As a result, the air-tight level and the outer wall insulation were penetrated by the beam. There is therefore an increasing tendency to build external walls that cross the various floors. Using ASSYplus VG full thread screws, edge beams can be secured quickly, efficiently and easily in the form of a simple shear connection. The footing beams must then be secured to the edge beams, again using ASSYplus VG. The screw-in template FT-fix is also suitable for comfortable, precise assembly (screw-in angle and screw spacing).

Abutment restoration

In old buildings, wooden footing beams are often damaged. Wood integrated in the masonry can be infected by humidity, fungus or insects. The beams may have rotted off or become heavily damaged at the point of support. Using laterally bolted reinforcing lugs, these points can be quickly and easily renovated and the load-bearing capacity of the beams is restored. This eliminates the need to completely replace the damaged beams.

Replacement of plugs and dowels in two-cut timber/timber joints

Precise installation is required to accurately execute traditional beam dowel joints. In practice, this often leads to implementation problems. A more aesthetically pleasing and more economical alternative is the creation of double shear timber/timber joints using ASSYplus VG screws. Installation differences can be easily compensated for with equivalent load capacities. Compared with the beam-dowel joint, a smaller diameter is sufficient due to the screws' tensile strength.

Wooden/concrete composite ceilings

Renovating a ceiling using a wood-concrete composite solution is a great method for increasing load-bearing capacity where beam spacing and support widths are particularly large or where very high nominal loads are involved. In this case, the partially screwed-in full thread screws act as shear connectors and absorb the shear flow between the timber beams and the concrete slab. This eliminates the time-consuming installation of steel shear connectors. The ASSYplus VG screw has obtained European Technical Approval (ETA13/0029) for this method

| |

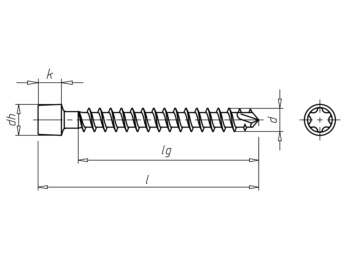

Nominal diameter (d) | 10 mm |

Length (l) | 120 mm |

Thread length (lg) (lg) | 97 mm |

Screw-thread length with drill tip (b) (b) | 97 mm |

Head type | Socket head |

Head diameter (dh) | 13.4 mm |

Head height (k) | 8 mm |

Internal drive | AW50 |

Thread type | Wood screw thread |

Thread design | Full thread |

Thread form | Single start thread |

Core diameter | 6.2 mm |

Shape of tip | Drilling tip |

Material | Hardened steel |

Surface | Zinc plated yellow |

Max. screw-in angle | 90 Degree |

Min. screw-in angle | 0 Degree |

Suitable for use in the following materials | Board ply wood (BSP), Wood, Derived timber product, Hardwood, LVL, Softwood, Construction beech |

Area of application | On rafter insulation, Beam reinforcement, Structural woodwork, Lateral compression reinforcement, Transverse reinforcement, Carrier doubling |

Approval | ETA-11/0190 |

Product weight (per item) | 39.500 g |

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!